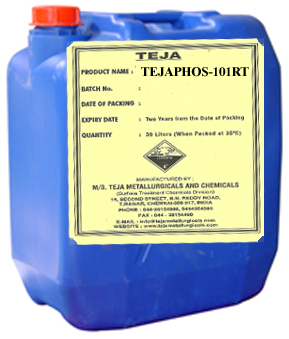

TEJA METALLURGICALS AND CHEMICALS

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to TEJA METALLURGICALS AND CHEMICALS

Zinc Phosphating Chemical

Product description

Teja phos 101RT is an accelerated cold Immersion phosphating process, which produces light to medium weight phosphate coating on iron and steel surfaces. The coating produced by Teja phos 101RT serves as an excellent base for paint and coating formed after surface condition with our (TejaActivator), is of fine crystalline structure and gives good gloss to the paint.

Teja phos 101RT phosphating process gives medium weight coating and protects. Iron and steel surfaces against rusting.

Product Specifications

Colour

Light green liquid

Odour

Slightly Pungent

Foaming Tendency

Nil

Reliability

Good

Handling

Avoid skin contact

Solubility

Good

pH

Acidic Range

Toxicity

Acidic

Flash Point

Nil

Pollution Hazard

Treatable

Product Operating Data

Process

Dip Process

Concentration

5%

Time

20-25 minutes

Temperature

R. T. 20 – 300C

Teja Activator

3 ml

Product Operating Procedure

Degreasing

Water Rinsing

Derusting

Water Rinsing

Activator

Phosphating (Teja phos 101RT)

Water Rinsing

Passivation

Drying

Product Application Equipments

Teja phos 101RT tank should be fabricated with 3 to 4 mm thick M.S. (or preferably SS 316) Plates with continuous current heating system.

Testing and control Procedure

TotalAcidity.

Pipette out 10 ml. of bath solution in a conical flask. Add a few drops of Indicator Phenolphthalein. Titrate with N/10 sodium Hydroxide until permanent pink colour appears. Bath pointage should be maintained between 18 to 22 ml. Adjust the pointage by adding Teja phos 101RT to the bath. For each pointage less add 150 ml of activator per 100 liters of bath.

Teja activator (accelerator) Test starch-iodide paper.

Dip a piece of starch lodide paper in the bath.

No Accelerator

Remains White

Insufficient Accelerator

Pale Mauve

Optimum

Blue to Dark Blue

Excess Accelerator

Black

It is very important to have the correct amount of Activator in the bath. Excess in the bath will cause excess sludge formation and wastage of Teja phos 101RT insufficient addition causes accumulation of Iron salts and throws the bath out of balance.

Titration of activator Pipette out 50 ml bath solution into flask. Add 5ml of concentrated H2SO4and mixed it well. Titrate it against N/10 KmNO4solution to a pink colour which will persist for a few seconds.

Normal limits for (activator) titration is 2.6 ml. Lower limit is preferable. Prior to titration starch iodide paper should be positive. Replenishment – Approximately 30 ml. of 25% Activator solution in water should be added to increase the activator titration by 1 ml.

Chemical Replenishment

Restore the bath to the working level by adding water to makeup evaporation loss and drag out losses. Check the Teja phos 101RT pointage.

Safety Measures

Teja phos 101RT is an acidic liquid material, and while handling proper care should be taken. Protect eye, skin by means of goggles, aprons, gloves, face shield etc. If it comes in contact with skin and eyes wash thoroughly with a flush of water and get medical advice. For further Information please refer our Material Handling and Personal safety Data Sheet No.2.

General Information

Corrosion Resistance: Excellent

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.